With our longstanding history of being at the top of the market we are committed to bringing our customers only the best in quality, service and reliability.

Econo-Pak is your contract packaging partner. Experience the assurance of working with a company that understands the intricacies of the packaging industry and is dedicated to elevating your products through exceptional packaging solutions.

Here at XPress 360, we pride ourselves on being a premier provider of contract packaging solutions, offering a diverse range of products, services, and capabilities to meet the varied needs of our esteemed clientele. With our unwavering commitment to excellence and extensive expertise in contract packaging, we stand ready to deliver innovative solutions that excel in quality and reliability...

Here at Vocational Improvement Program, Inc., we take immense pride in our role as a premier provider of contract packaging solutions, offering a diverse range of products, services, and capabilities to meet the varied needs of our esteemed clientele. With our unwavering commitment to excellence and extensive expertise in contract packaging, we stand ready to deliver innovative solutions that...

Here at Sol-Tech Services, we pride ourselves on being a leading provider of contract packaging solutions, offering a comprehensive range of products, services, and capabilities to meet the diverse needs of our esteemed clientele. With our unwavering commitment to excellence and extensive expertise in contract packaging, we stand ready to deliver innovative solutions that excel in quality,...

More Food Packaging Companies

Food is enclosed in packaging during shipping, storage, and retail sale to guard against damage, tampering, contamination, spoiling, and pest attacks. Information on the contents, ingredients, nutritional value, cooking directions (if applicable), and shelf life are frequently listed on the box's label. Food packaging protects contents from infection, manipulation, and damage. Therefore, it is important to choose and design the package such that there are no unfavorable interactions between it and the food. Bags, bottles, cans, cartons, and trays are a few examples of packaging kinds.

Reasons for Using Food Packaging

There are numerous significant purposes for food packaging. Some of these reasons are listed below.

- Containment - Quite simply, food items need to be contained once manufactured during transport and storage. The best packaging for granulated goods, for example, is made of paper and has a sealing device to stop moisture from penetrating the product.

- Protection - The packaging must protect the food from

- biological invaders like rodents, bugs, and germs.

- mechanical damage, for example, vibration, compressive forces, and product abrasion.

- chemical deterioration from oxidation, moisture transport, and UV light.

- Communication - For consumer use, packaged food must be identified, mostly through label text and visuals. It is possible by adopting unique food packaging shapes, such as pizza boxes and fruit juice containers.

- Environmental Issues - We must be willing to recycle, reuse, or reduce the packaging size to protect the environment.

- Package Safety - Researchers must ensure that a certain type of food packaging is safe to use for the food under consideration and that there are no negative interactions between the packaging and the food.

- Product Accessibility - When the user is ready to utilize the product, it must be easily accessible thanks to the packaging.

- Traceability -The ability to follow the movement of a food through specified stage(s) of production, processing, and distribution," according to the Codex Alimentarius Commission. The three goals of traceability are improvement of supply management, facilitation of trace-back for food safety and quality, and differentiation and marketing of foods with subtle or undetectable qualities.

Applications for Food Packaging

Food packaging is applied to many different types of food; below are some of the sectors where it is applied.

- Meat

- Frozen Food

- Baked Goods and Cooked, or Prepared, Meals

- Takeaway Meals

- Seafood

- Spices

- Dairy Items Such as Yogurt and Ice Cream

- Raw Materials

Types of Food Packaging

Numerous types of food packaging materials are available since the packaging requirements for various types of food vary, including:

- Cans

- Cartons

- Aseptic Processing

- Pallets

- Flexible Packaging

- Wrappers

- Trays

- Bags

- Boxes

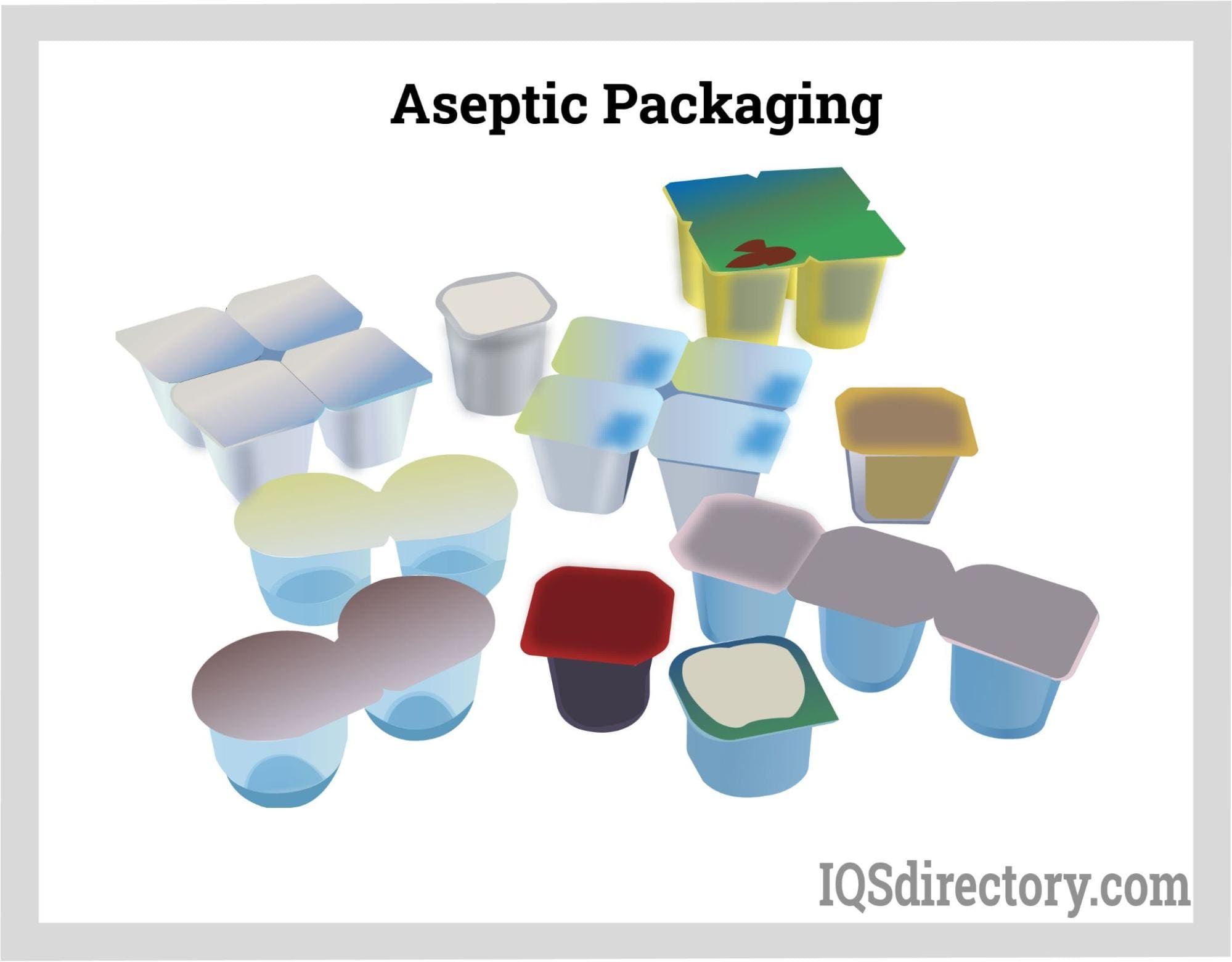

Aseptic Packaging

Aseptic packaging is made by covering a paper and aluminum mixture with a layer of polyethylene. It is used for foods that must remain sterile, such as milk, drinks containing milk, and liquid eggs.

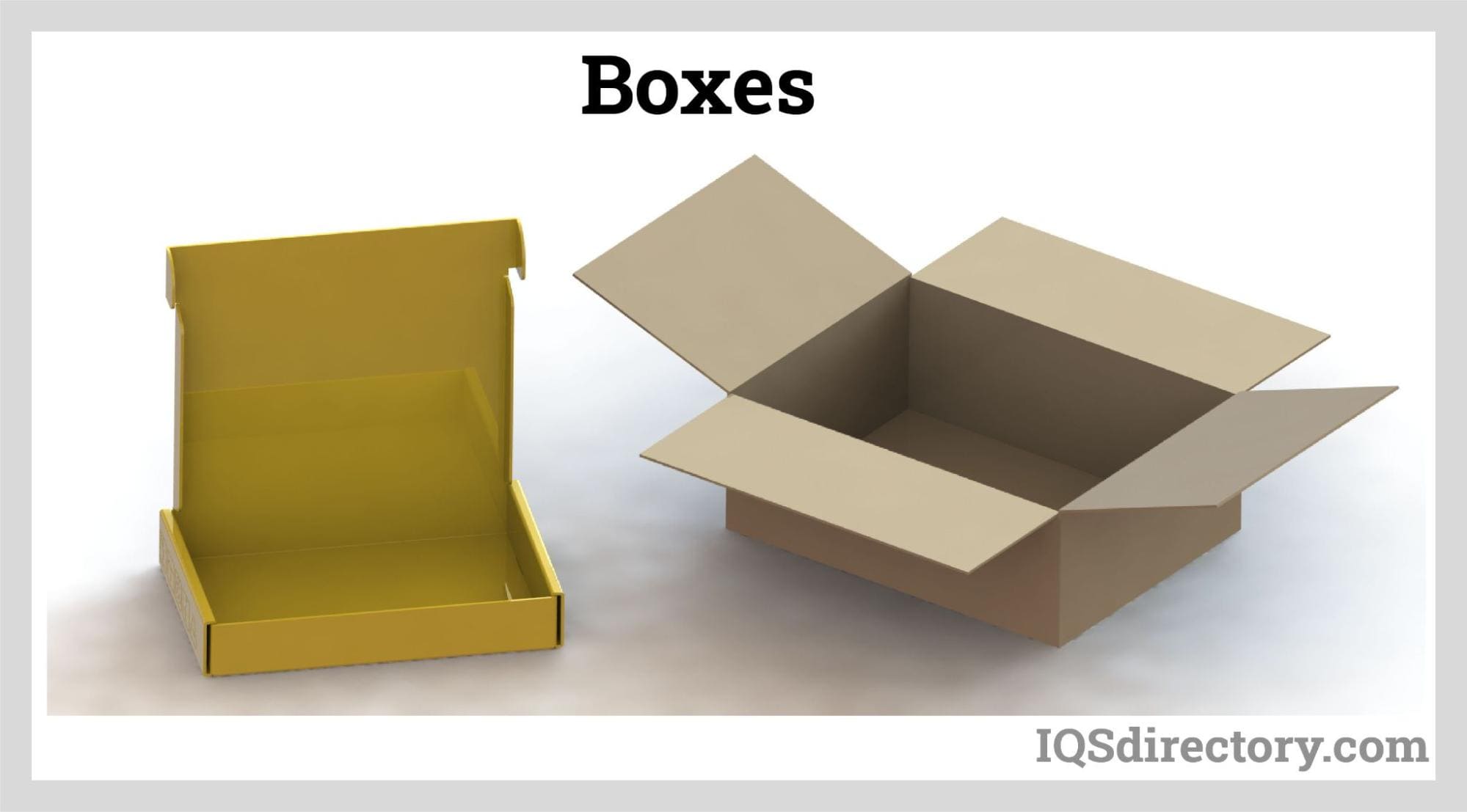

Boxes

The box is among the most widely used food packaging materials. Since they could be made of metal, wood, or corrugated fiberboard, they are more enduring. Foods including cereal, frozen pizza, snack crackers, and biscuits are frequently housed in them.

Cartons

Plastic or paraffin coats corrugated cardboard making cartons more resistant to moisture. They come in various food packaging designs, such as aseptic cartons, gable-top cartons, folding cartons, and egg cartons.

Cans

Cans are made by covering steel or other thin metal vessels with tin to prevent corrosion. As a result of the opaque nature of the container, they are ideal for keeping food fresh and shielding it from light. Many meals, including soup, meats, vegetables, fruit, and gravy, are packaged in cans.

Flexible Packaging

Flexible packaging is a non-rigid container that can take on any shape. Like bags, it shields the items from the elements and increases their shelf life. Salads in bags are an illustration of flexible packaging.

Bags

Bags are often composed of thin, plastic material to keep the food from encountering the air and environment. Snacks like chips and pretzels, and fruits and vegetables like apples and potatoes can all be bagged.

Pallets

Pallets are used to convey a lot of food containers. The products are often shrink-wrapped for enhanced security.

Wrappers

Wrappers are lightweight plastic packaging that shields food from the elements. They're utilized for things like candy and granola bars.

Trays

Using flat, strong paperboard with raised sides that hold the product inside the container, trays are made. They are effective with foods like drinks, meat, and plant seeds.

Advantages of Food Packaging

- All important information about the product, for example, ingredients, cooking instructions, and expiration date is shown on the packaging.

- The product is protected from spoilage by packaging.

- Preventative measures include packaging.

- Packaging promotes cleanliness.

- Packaging shields the item.

- Packaging lowers expenses.

- Packaging is used as an advertising medium by manufacturing companies.

Disadvantages of Food Packaging

- Transport expenses are higher for heavier packages than for other types of packing.

- Some packaging provides less resilience to thermal shock, scratches, and fractures than other materials.

- More flexible dimensions may be created than containers made of metal or plastic.

- Risks from glass splinters or particles in meals could be quite serious.

Choosing the Proper Food Packaging Company

To make sure you have the most constructive outcome when purchasing Food Packaging from a Food Packaging Supplier, it is important to compare at least 6 Companies using our list of Food Packaging manufacturers. Each Food Packaging Supplier has a business profile page that highlights their areas of experience and capabilities and a contact form to directly communicate with the manufacturer for more information or request a quote. Review each Food Packaging company website using our patented website previewer to get an idea of what each business specializes in, and then use our simple RFQ form to contact multiple Food Packaging companies with the same message.

Cardboard Tubes

Cardboard Tubes Carrying Cases

Carrying Cases Contract Packaging

Contract Packaging Corrugated Boxes

Corrugated Boxes Dot Peening Machines

Dot Peening Machines Labeling Machinery

Labeling Machinery Marking Machinery

Marking Machinery Packaging Equipment

Packaging Equipment Palletizers

Palletizers Plastic Bags

Plastic Bags Sewing Contractors

Sewing Contractors Tape Suppliers

Tape Suppliers Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

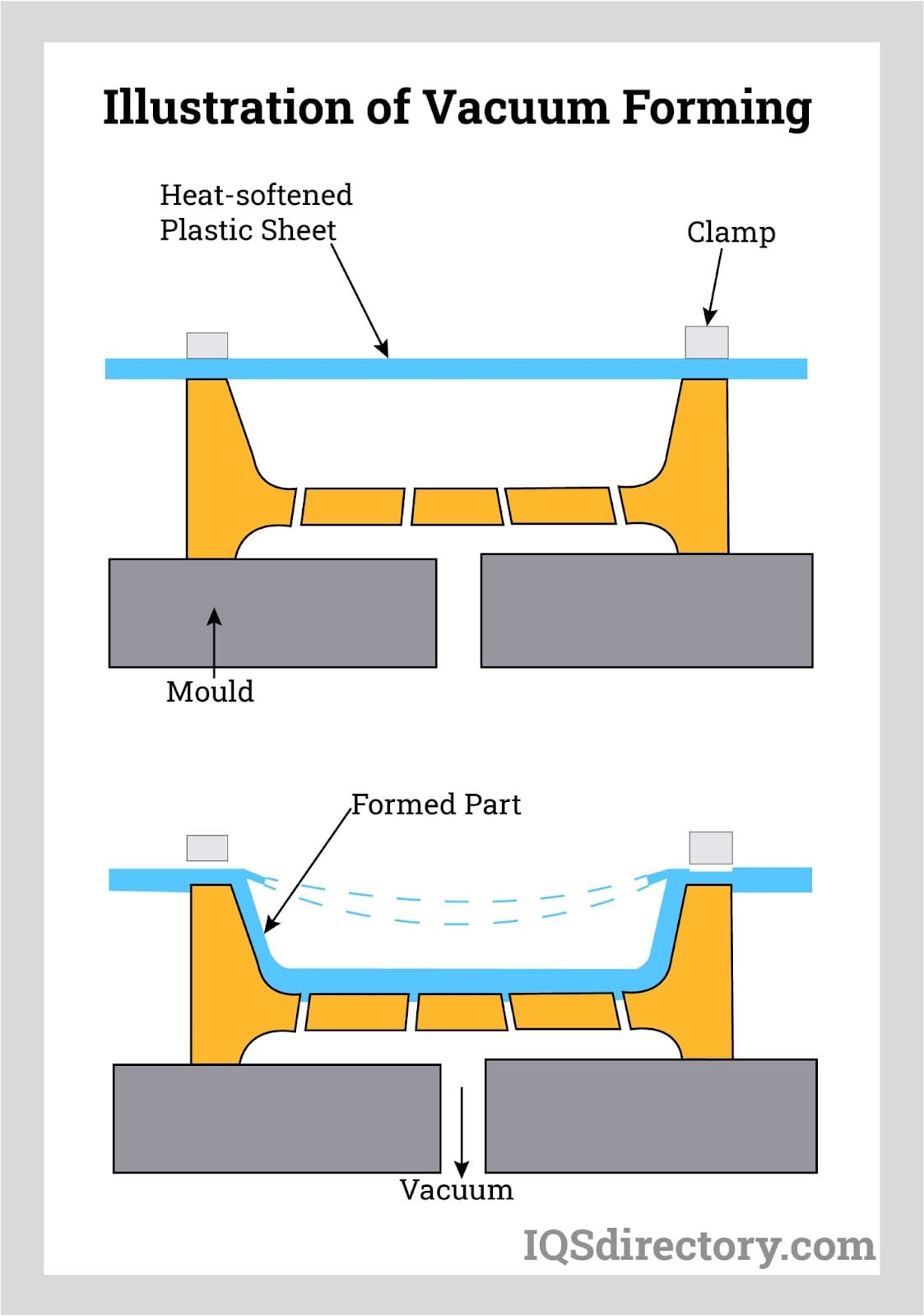

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services