With our longstanding history of being at the top of the market we are committed to bringing our customers only the best in quality, service and reliability.

Econo-Pak is your contract packaging partner. Experience the assurance of working with a company that understands the intricacies of the packaging industry and is dedicated to elevating your products through exceptional packaging solutions.

Here at XPress 360, we pride ourselves on being a premier provider of contract packaging solutions, offering a diverse range of products, services, and capabilities to meet the varied needs of our esteemed clientele. With our unwavering commitment to excellence and extensive expertise in contract packaging, we stand ready to deliver innovative solutions that excel in quality and reliability...

Here at Vocational Improvement Program, Inc., we take immense pride in our role as a premier provider of contract packaging solutions, offering a diverse range of products, services, and capabilities to meet the varied needs of our esteemed clientele. With our unwavering commitment to excellence and extensive expertise in contract packaging, we stand ready to deliver innovative solutions that...

Here at Sol-Tech Services, we pride ourselves on being a leading provider of contract packaging solutions, offering a comprehensive range of products, services, and capabilities to meet the diverse needs of our esteemed clientele. With our unwavering commitment to excellence and extensive expertise in contract packaging, we stand ready to deliver innovative solutions that excel in quality,...

More Cosmetic Packaging Companies

Because of the extensive range of cosmetic products available, an equally wide range of packaging designs is necessary to accommodate them.

The long list of cosmetic product packaging configurations includes tubes, pumps, pencils, compacts with mirrors, cases, bottles, jars and many more. These containers often must be air and water-tight in order to keep creams, pastes, lotions, powders, gels, cakes, waxes and jellies from spilling or become dried by contact with air.

Other cosmetic products like mascara, concealer, eye shadow, eye liner, lip stick, blush, lotions, creams, nail polish and body spray all require specialized packaging to create the right storage atmosphere and to allow for easy application. Some liquids like foundation and nail polish are stored in glass bottles, while lotions, which would be difficult to extract from glass, are packaged in plastic containers. Jars can feature pop-on or threaded twist-off lids, and bottles can be fitted with pumps and caps to dispense their products.

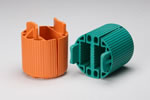

Cosmetic packaging can be made out of plastic, metal, glass and even polished wood in some cases. The majority of plastic cosmetic packaging products are made of acrylics, polyethylene terephthalate (PET), polystyrene (PS), polyethylene (PE) or polypropylene (PP). There are exceptions, but these materials are so widely used because they are inexpensively and easily formed. They can also be lightweight, non-porous and hypoallergenic.

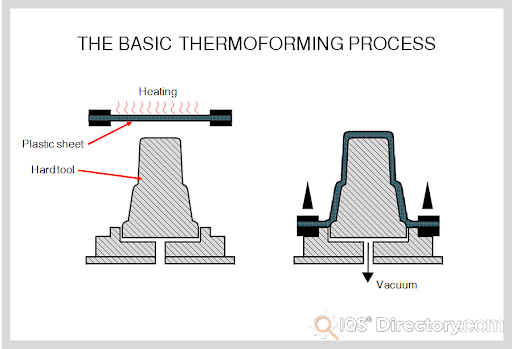

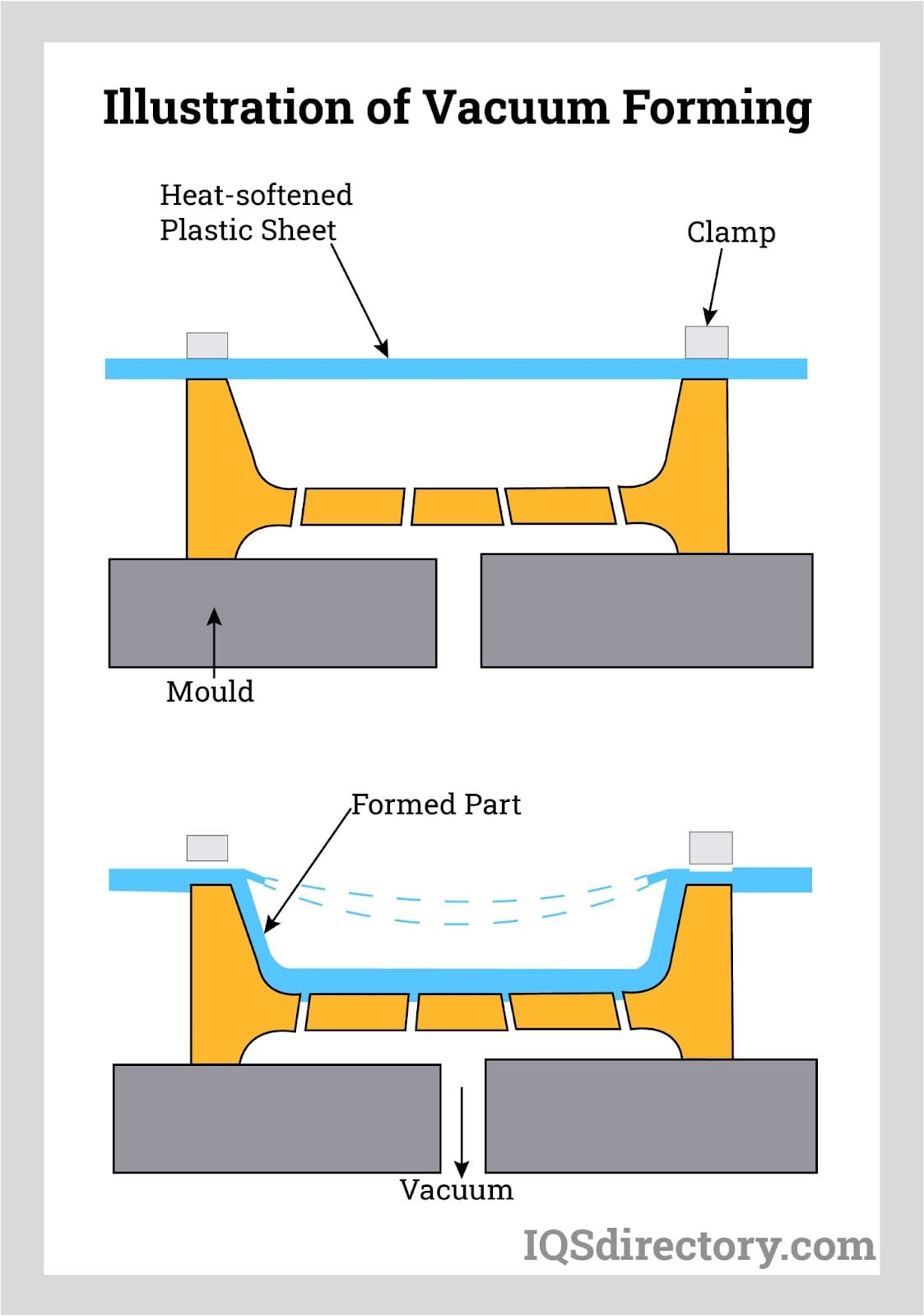

Most of the cosmetic packaging products made using these plastics are formed by blow molding. Blow molding begins by heating raw plastic material until it is molten. The molten plastic can be mixed in with coloring agents and other additives to improve the appearance of the finished product. The molten plastic is then injected into a mold cavity that is shaped like the intended packaging product. Compressed air is forced into the mold, forcing the plastic to take the mold's shape and become hollow in its middle.

Once the plastic has taken its shape, it is allowed to cool and harden and is then ejected from the mold. The process is fast, accurate and highly repeatable. Thousands of identical containers are manufactured in high volumes through this molding process. Often, the cosmetic packagers assist customers with concept and brand development, as well as the exterior design of the logo and label.

Cardboard Tubes

Cardboard Tubes Carrying Cases

Carrying Cases Contract Packaging

Contract Packaging Corrugated Boxes

Corrugated Boxes Dot Peening Machines

Dot Peening Machines Labeling Machinery

Labeling Machinery Marking Machinery

Marking Machinery Packaging Equipment

Packaging Equipment Palletizers

Palletizers Plastic Bags

Plastic Bags Sewing Contractors

Sewing Contractors Tape Suppliers

Tape Suppliers Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services