With our longstanding history of being at the top of the market we are committed to bringing our customers only the best in quality, service and reliability.

Econo-Pak is your contract packaging partner. Experience the assurance of working with a company that understands the intricacies of the packaging industry and is dedicated to elevating your products through exceptional packaging solutions.

Here at XPress 360, we pride ourselves on being a premier provider of contract packaging solutions, offering a diverse range of products, services, and capabilities to meet the varied needs of our esteemed clientele. With our unwavering commitment to excellence and extensive expertise in contract packaging, we stand ready to deliver innovative solutions that excel in quality and reliability...

Here at Vocational Improvement Program, Inc., we take immense pride in our role as a premier provider of contract packaging solutions, offering a diverse range of products, services, and capabilities to meet the varied needs of our esteemed clientele. With our unwavering commitment to excellence and extensive expertise in contract packaging, we stand ready to deliver innovative solutions that...

Here at Sol-Tech Services, we pride ourselves on being a leading provider of contract packaging solutions, offering a comprehensive range of products, services, and capabilities to meet the diverse needs of our esteemed clientele. With our unwavering commitment to excellence and extensive expertise in contract packaging, we stand ready to deliver innovative solutions that excel in quality,...

More Clamshell Packaging Companies

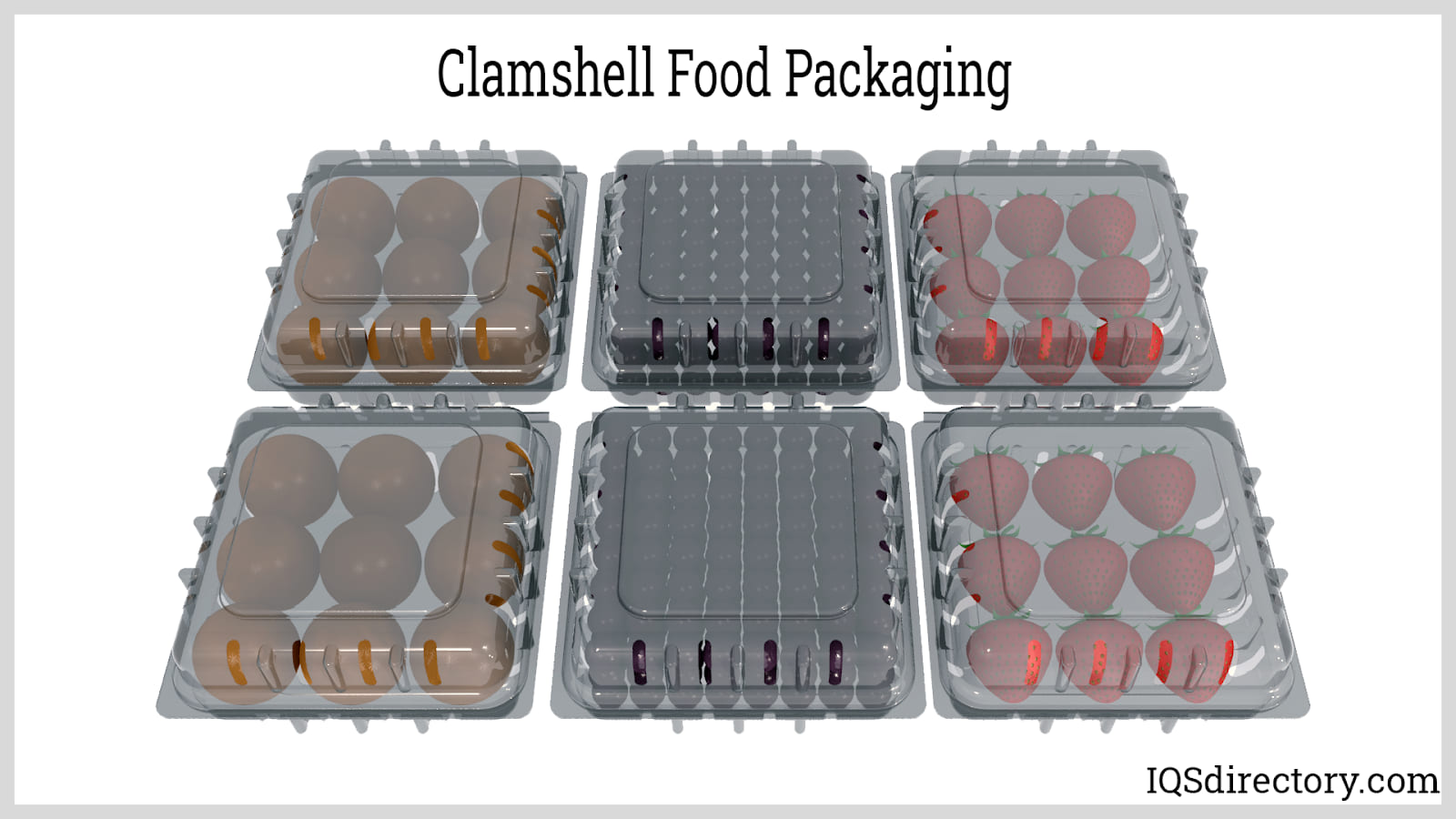

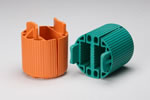

Clamshells are single-use containers with hinged lids and closures that can either be constructed to be permanently sealed or to be re-closable. Typically, they are composed of plastic since, compared to cardboard or other substitutes, this material is stronger, easier to construct, and lighter, conserving energy during transportation. However, they can also be produced from recycled paper, cardboard, paperboard, and Styrofoam™. They are composed of two "shells" that are exactly the same. The shells then have tabs on one side and are linked to one another by that side. They can be closed and locked shut thanks to these tabs. They open and close similarly like real clamshells.

How Clamshell Packaging is Made

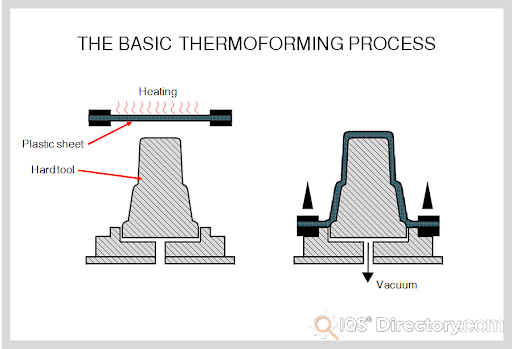

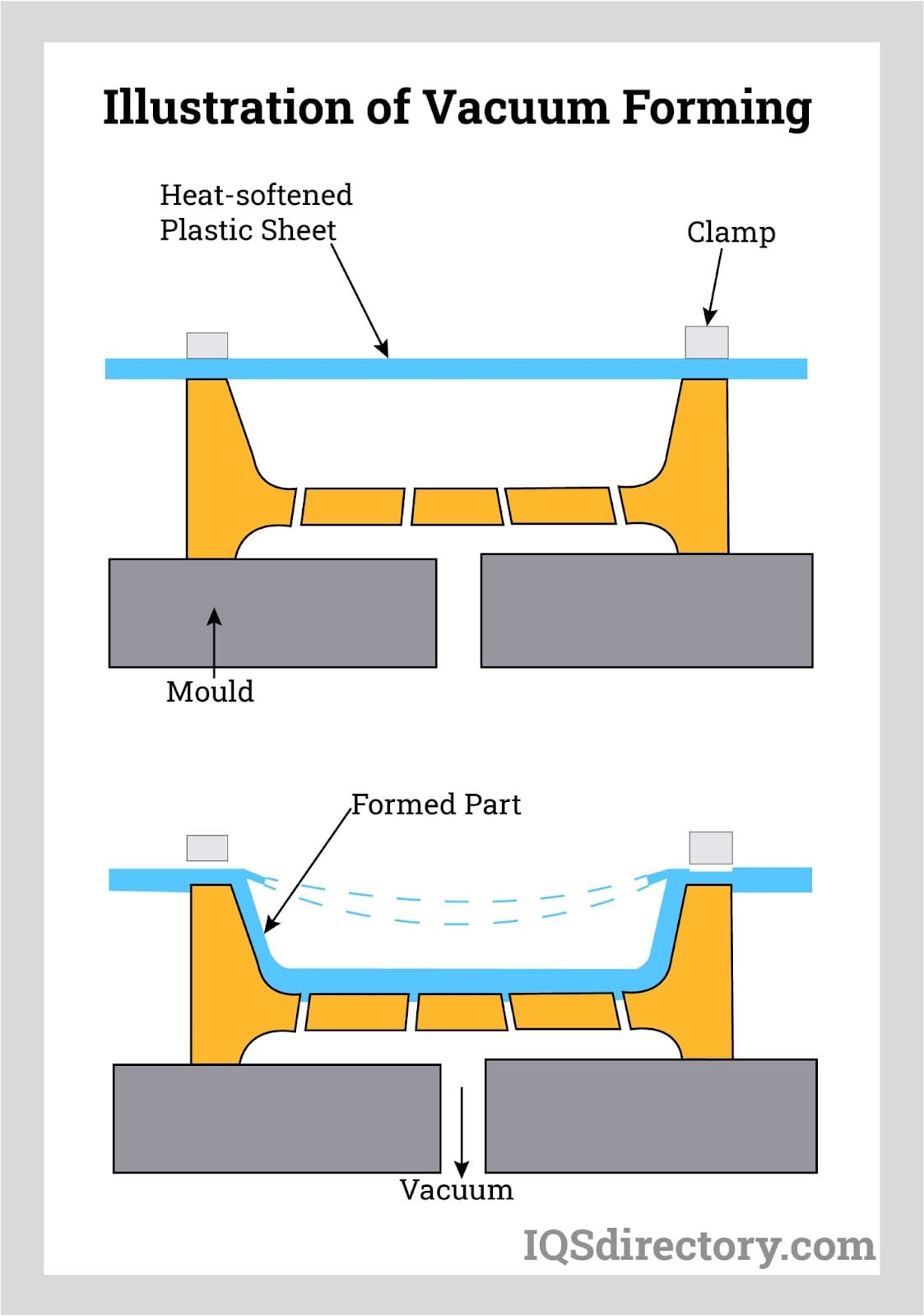

Clamshells are normally created by thermoforming clear plastic. PVC (polyvinyl chloride) is the most often utilized material. Thermoforming involves heating thermoplastic material and covering a mold with it until it cools. In this case, the mold resembles a clam. There are different gauges (thicknesses) of plastic materials available when creating clamshell packaging and the gauge selected is typically based on the item intended to be packaged inside. Whether rolled sheets (thin gauge) or pre-cut stacked sheets are used in the manufacturing process depends on the material's thickness (heavy gauge). The disposable packaging market, particularly in retail marketplaces, is dominated by thin gauge material. After being heated, the material passes onto the forming stage, where it is forced onto the mold under pressure or under a vacuum (vacuum forming). Vacuum forming, in general, refers to all sheet-forming techniques. Greater detail and rough surfaces are produced in the final product thanks to this technique's enhanced pressure and, with the additional pressure used during the forming process, sharp corners can be produced. The forms are die-cut during the following phase in the process

Different procedures are employed by manufacturers to create other types of clamshell packages. Although thermoforming is typically used to create clamshells, blow molding, for example, may also be used. PET (polyethylene terephthalate) products of various grades, each with a particular function, are produced using this distinctive technique. PET is 100% recyclable, regardless of grade. But there are a number of difficulties with recycling PET thermoform containers.

Packaging Applications for Clamshells

- Clamshells are typically used to package a variety of foods, including sandwiches, all types of pies, cookies, bread, burgers, pastries, frozen lobster tails, salads, and many more food items.

- Different retail outlets like food carts and catering trucks use clamshells as do markets and restaurants.

- Sometimes, clamshells made of hybrid carded-packaging materials are used to package nails, screws, and small home repair items. Also, clamshells are used for the storage of toys and other small accessories.

Benefits of Clamshells

- Transparent: Customers want to know that the things they are buying are in the condition they were promised to be in, free of errors, defects, or tampering. Clamshell packaging is a popular choice among businesses due to its high-clarity visibility, which provides clients with the security they require. Customers who buy goods in clamshell packaging, whether they are food items or retail goods, are not left in the dark about what the goods inside look like. Instead, they can look closely at the package to make sure it meets all of their requirements. Carefully-placed cutouts can be created by packaging designers to highlight specific product features and increase product exposure.

- Design versatility: Plastic companies are able to produce any size and shape of clamshell package one may require thanks to the wonders of thermoforming. Whether a customer requires something straightforward like a clamshell carry-out container, something intricate with a unique inside tray, or a container with many cavities for various product components, this is possible through thermoforming clamshell containers. Clamshells may be created with hanger hooks or punch holes so they can be hung for storage. They can be created to stack on one another. Customers selling their goods in a large warehouse should also consider standalone clamshells as a great packaging, storing, and shipping option. This personalized packaging not only protects items from the elements but also enhances their client appeal by making them look fresh and new.

- High security: Clamshell packaging is not just very protective but, as discussed, is also transparent when using plastic material. Clamshell packaging is frequently used by businesses to protect expensive goods, such as cell phones and phone cases. Although clamshell packages may also have a different seal, businesses still frequently employ them in retail environments because they can shield goods from tampering from the outside. Additionally, these containers are strong enough to guard against product damage and temperature variations while being handled and sent. Clamshell packages offer the same safeguards for food goods, fostering consumer confidence by assuring them that the food is safe to consume.

Drawbacks of Clamshell Packaging

- Perhaps the biggest drawback of utilizing clamshell packages is that they are difficult to recycle. Some materials utilized to create clamshell packaging may not be recyclable or the packages themselves do not easily process at recycling centers because of their features (like the rigidity of many packages make it extremely difficult to process). Additionally, clamshell packages may become contaminated by the items they are holding and, thus, cannot be recycled.

Choosing the Proper Clamshell Packaging Manufacturer

To make sure you have the most beneficial outcome when purchasing Clamshell Packaging from a Clamshell Packaging Supplier, it is important to compare at least 4 or 5 Suppliers using our list of Clamshell Packaging manufacturers. Each Clamshell Packaging Manufacturer has a business profile page that highlights their areas of experience and capabilities and a contact form to directly communicate with the manufacturer for more information or request a quote. Review each Clamshell Packaging business website using our patented website previewer to get an idea of what each company specializes in, and then use our simple RFQ form to contact multiple Clamshell Packaging businesses with the same quote.

Cardboard Tubes

Cardboard Tubes Carrying Cases

Carrying Cases Contract Packaging

Contract Packaging Corrugated Boxes

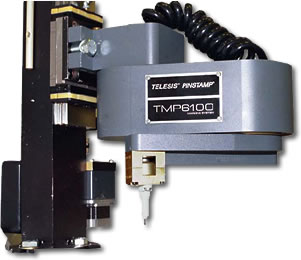

Corrugated Boxes Dot Peening Machines

Dot Peening Machines Labeling Machinery

Labeling Machinery Marking Machinery

Marking Machinery Packaging Equipment

Packaging Equipment Palletizers

Palletizers Plastic Bags

Plastic Bags Sewing Contractors

Sewing Contractors Tape Suppliers

Tape Suppliers Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services