Contract packaging, or co-packing, has extensive applications across various industries, each with its specific requirements and benefits. In the food and beverage sector, contract packaging services play a critical role in ensuring the efficient and reliable packaging of products. Read More…

With our longstanding history of being at the top of the market we are committed to bringing our customers only the best in quality, service and reliability.

Founded in 1987, Brisar Delvco Industries, Inc., is a leader in turn-key Contract Packaging Solutions. We provide a broad range of in-house services including blister packaging, blister carding, medical device packaging, pouching dietary supplements, OTC drugs, overwrapping, Direct Mail promotional packaging, auto-cartoning, along with other packaging processes. All under one umbrella in a...

At Akers Packaging Service Group, we take pride in delivering comprehensive packaging solutions that go far beyond simply supplying materials. Our strength lies in contract packaging, where we bring together decades of expertise, state-of-the-art facilities, and a dedicated team to manage packaging projects from start to finish.

Based in California, Teamwork Packaging specializes in all aspects of turnkey packaging. We provide innovative packaging solutions in response to the changing needs of the packaging industry. Our custom packaging displays will meet and exceed your specific packaging needs. Some of our services include auto-bagging, cello wrapping, coding, shrink wrapping, sleeve bundling and more. Call us today!

At RCS Empowers, Inc., we take pride in providing high-quality contract packaging services that help our partners streamline production and meet their customers’ needs efficiently. We understand that every packaging project is unique, which is why we offer flexible solutions designed to handle a wide range of products, from consumer goods to industrial materials.

More Contract Packaging Companies

Contract packaging, also known as co-packing, is a vital service that supports a broad spectrum of industries by outsourcing the packaging process to expert third-party contract packagers. From food and beverage to pharmaceuticals, electronics, and consumer goods, contract packaging companies enable businesses to streamline their supply chains, reduce operational costs, and accelerate time-to-market with professional, compliant, and innovative packaging solutions.

This comprehensive guide explores the applications, benefits, materials, processes, machinery, and decision factors involved in contract packaging. If you’re seeking to understand how co-packing can elevate your business or looking for the best contract packaging providers, read on for actionable insights and industry expertise.

What Applications Use Contract Packaging?

Contract packaging (or co-packing) refers to outsourcing the packaging of products to a specialized packaging partner, rather than handling it in-house. This strategic move allows businesses to focus on core competencies while leveraging the capabilities and infrastructure of experienced contract packaging companies. Below, we examine key applications and sectors leveraging contract packaging as of March 08, 2025:

- Food and Beverage Contract Packaging

- Applications: Co-packers handle the packaging of snacks, ready-to-drink beverages, frozen meals, sauces, dry goods (cereals, spices), condiments, and even functional foods or supplements.

- Why: Outsourcing enables companies to access food-safe facilities that comply with FDA, HACCP, and SQF standards. Co-packers manage processes such as bottling, pouch filling, vacuum sealing, and retort pouch packaging. Major brands like Keurig Dr Pepper utilize co-packers for regional bottling, while emerging brands scale up without massive capex investment.

- Example: An organic snack company outsources stand-up pouch filling to a co-packer with automated lines, achieving high throughput and ensuring shelf life consistency.

- Consumer Goods and Personal Care Packaging

- Applications: Cosmetics (creams, serums, lipsticks), household cleaners, detergents, air fresheners, and personal care products (shampoos, soaps, lotions, razors).

- Why: Co-packers offer specialized equipment for filling, capping, labeling, and blister packaging. They can manage diverse packaging formats (tubes, jars, sachets, unit-dose packs) and ensure regulatory compliance (e.g., for allergen or ingredient labeling). Startups such as Dollar Shave Club leverage co-packers to scale production without building their own plants.

- Example: A skincare brand partners with a co-packer to fill, seal, and label 50,000 tubes per month, ensuring retail readiness and regulatory accuracy.

- Pharmaceutical and Healthcare Packaging

- Applications: Prescription drugs, over-the-counter (OTC) medications, nutraceuticals, medical kits, injectables, diagnostic devices, and blister packs for tablets or capsules.

- Why: Compliance is critical—co-packers provide GMP-certified cleanrooms, tamper-evident seals, serialization, and validation processes. Major pharma companies like Pfizer outsource packaging for efficiency and regulatory assurance.

- Example: A generics producer contracts a co-packer for blister-packaging 1 million tablet packs, ensuring traceability and tamper-proof sealing.

- Retail and E-Commerce Packaging

- Applications: Subscription boxes, gift sets, promotional packaging, Amazon FBA-compliant repackaging, custom kitting, and bulk-to-individual repackaging.

- Why: Co-packers provide rapid, flexible kitting and assembly for direct-to-consumer (D2C) brands. They handle seasonal surges (e.g., holiday gift sets), compliance with retailer requirements, and efficient order fulfillment for online sellers.

- Example: A toy company outsources assembly and shrink-wrapping of 10,000 custom gift sets for the peak holiday season.

- Industrial and Chemical Product Packaging

- Applications: Lubricants, adhesives, paints, solvents, cleaning agents, and other bulk chemicals in drums, pails, cans, sachets, or pouches.

- Why: Contract packagers manage hazardous materials in accordance with OSHA, DOT, and EPA regulations. They offer heavy-duty filling, custom labeling, and safety sealing for hazardous or sensitive goods, enabling smaller firms to avoid the cost of in-house certifications.

- Example: A paint manufacturer contracts aerosol can filling and labeling for 20,000 units, ensuring GHS-compliant safety communication.

- Electronics and Technology Packaging

- Applications: Consumer electronics, USB drives, batteries, chargers, cables, PC components, and accessories.

- Why: Co-packers offer ESD-safe assembly environments and custom foam inserts, ensuring product safety and retail appeal. Companies such as Anker outsource retail blister pack assembly for high-volume electronics launches.

- Example: A startup contracts the co-packing of 50,000 USB drives in clamshell packaging for distribution to leading retailers.

- Seasonal and Promotional Product Packaging

- Applications: Limited-edition holiday gift sets, event giveaways, promotional bundles, and sample packs.

- Why: Co-packers provide fast, flexible turnaround for short-run, time-sensitive projects. Brands like Coca-Cola rely on co-packers for special-edition packaging (e.g., holiday cans in custom sleeves).

- Example: A confectionery company outsources the assembly and wrapping of 100,000 Halloween treat packs in under four weeks.

Industry Context and Trends

Contract packaging is indispensable where production volumes fluctuate, regulatory demands rise, or specialized equipment is needed. The global contract packaging market reached $70 billion in 2023 (Packaging Digest), with food (40%) and pharmaceuticals (20%) as dominant sectors. Leading contract packaging companies like PackSavvy Solutions and Assemblies Unlimited offer turnkey co-packing services, enabling brands to avoid multi-million-dollar investments in automated machinery. For companies seeking to expand quickly or enter new markets, contract packaging provides speed, compliance, and scalability without the overhead of in-house operations.

Products Produced by Contract Packaging

A wide variety of packaging products are manufactured in contract packaging operations, including blister packs, clamshells, pouches, food containers, shrink wrap, cartons, unit dose packaging, flexible packaging, and more. These packaging formats are selected based on product type, regulatory needs, and branding objectives.

Packaging solutions typically fall into three main categories: primary, secondary, and tertiary packaging. Understanding the differences is crucial for businesses evaluating contract packaging options.

Primary Packaging

Primary packaging is the material that directly contacts and contains the product, serving as the first line of protection. Examples include bottles for beverages, pouches for snacks, blister packs for pharmaceuticals, and jars for food products. Primary packaging is critical for product safety, shelf life, branding, and regulatory compliance.

Secondary Packaging

Secondary packaging surrounds the primary packaging to provide additional protection and facilitate grouping for shipping, display, or retail sales. Common forms include cartons, cardboard boxes, shrink-wrapped trays, and multipacks. Secondary packaging also offers branding and marketing opportunities at the point of sale.

Tertiary Packaging

Tertiary packaging enables the safe and efficient handling of products in bulk during shipping and storage. Examples include pallets, stretch wrap, and large corrugated boxes. Tertiary packaging is essential for logistics, warehouse management, and large-scale distribution.

The Evolution and History of Contract Packaging

While packaging dates back to the origins of trade and commerce, the contract packaging industry as we know it evolved in response to technological advances, regulatory requirements, and modern supply chain demands.

- Early Innovations: The use of tinplate in Bohemia (now the Czech Republic) in the 17th century and the introduction of airtight canning by Nicholas Appert in France in the early 1800s set the stage for modern food and product packaging.

- Industrialization: The commercial production of corrugated boxes began in England in 1817, and innovations in paperboard and pre-cut cartons by Robert Gair in 1890 revolutionized packaging for mass markets.

- Wartime Advances: World War II drove the development of secure, functional packaging for military logistics, leading to the establishment of mil-spec packaging regulations and the rise of standardized packaging systems.

- Academic Foundations: Michigan State University launched the first Packaging Engineering degree in 1952, cementing packaging as a distinct discipline. The subsequent establishment of the MSU School of Packaging provided a foundation for industry best practices.

- Modern Era: Environmental concerns in the 1980s and 1990s led contract packaging firms to adopt recycled and sustainable materials, in response to both regulations and consumer demand. The formation of the Contract Packaging Association (CPA) in 1992 unified manufacturers and elevated industry standards. Continued growth since 2008 reflects the increasing demand for specialized, flexible packaging services worldwide.

Materials Used in Contract Packaging

Choosing the right packaging material is essential for product safety, visual appeal, sustainability, and regulatory compliance. Common packaging materials used by contract packagers include:

Plastics

- HDPE (High-Density Polyethylene): Durable, chemical-resistant, and recyclable, HDPE is used for bottles, food storage, and industrial containers. Its strength and versatility make it a staple for primary packaging.

- LDPE (Low-Density Polyethylene): Flexible and lightweight, LDPE is ideal for film, plastic wrap, squeeze bottles, and some cartons. It’s valued for its flexibility and moisture barrier properties.

- PET (Polyethylene Terephthalate): Known as polyester, PET is widely used for beverage bottles, food packaging, and flexible film applications. Its clarity and strength are prized for both primary and secondary packaging.

Papers and Boards

- Paperboard: Lightweight and strong, paperboard is used for cartons, boxes, sleeves, and trays. It can serve as both primary and secondary packaging depending on application and design.

- Fiberboard: Includes corrugated fiberboard for shipping boxes and rigid board for protective packaging. Used primarily for secondary and tertiary packaging to ensure transit safety.

Glass

- Glass jars and bottles are used for foods, beverages, and pharmaceuticals requiring chemical inertness, high clarity, and strong shelf appeal. Glass provides excellent barrier properties and is fully recyclable.

Metals

- Aluminum: Used for cans, containers, and foil packaging. Aluminum offers leak-proof protection, corrosion resistance, and thermal benefits, making it ideal for food, beverage, and pharmaceutical packaging.

- Aluminum Foil: Provides a high barrier to light, moisture, and contaminants. Common in flexible food packaging, pharmaceutical blister packs, and insulated wraps.

Sustainable and eco-friendly packaging materials are increasingly prioritized, with many contract packaging companies offering biodegradable plastics, recycled paperboard, and reusable packaging solutions to support green initiatives.

Contract Packaging Service Details and Design Process

Successful contract packaging projects begin with detailed needs analysis and design consultation. Here’s a typical workflow:

- Package Type Definition: Determining whether primary, secondary, or tertiary packaging is needed, based on product characteristics and logistics requirements.

- Needs Assessment: Analyzing factors such as shelf life, marketing goals, compliance (FDA, GMP, GHS, etc.), labeling, branding, environmental considerations, production volume, budget, and lead time.

- Material and Design Selection: Choosing suitable packaging materials and graphics. CAD software, rapid prototyping, and 3D modeling are used for concept visualization and structural testing.

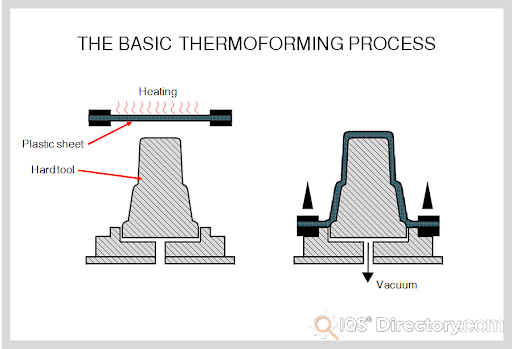

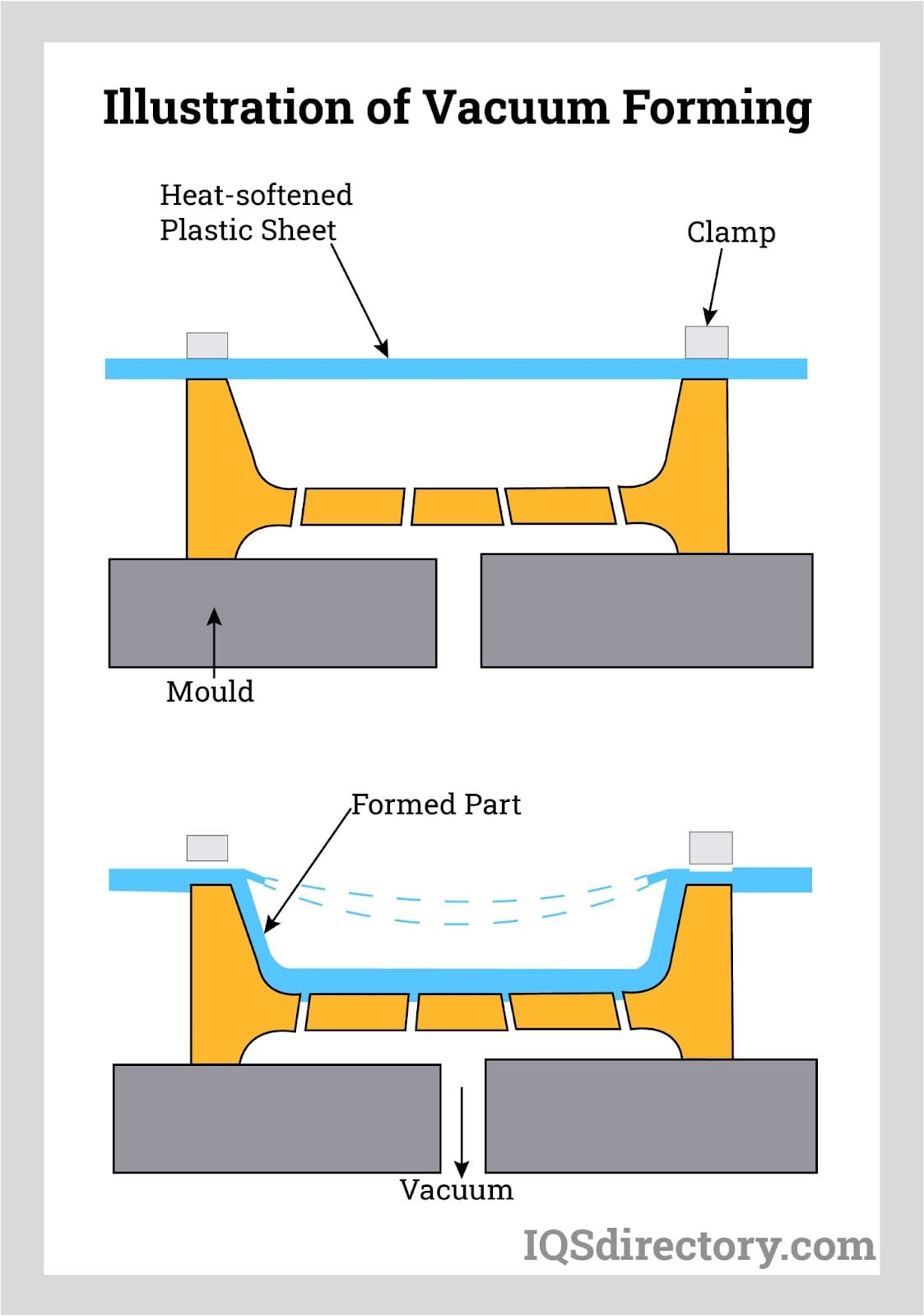

- Process Selection: Deciding on packaging methods—plastic molding, heat sealing, vacuum sealing, or automated filling—based on product type and compliance needs.

- Customization and Labeling: Designing custom labels and graphics to maximize retail impact and regulatory accuracy. Many contract packagers offer in-house graphic design for cohesive branding.

- Production, Storage, and Distribution: Contract packaging operations often handle bulk storage, labeling, palletizing, and direct-to-retail or e-commerce fulfillment, streamlining the entire supply chain from production to delivery.

Want to know what packaging design or material best suits your product?

Ask about shelf life, transport conditions, regulatory compliance, or sustainable packaging options—experienced contract packagers can guide you to the right solution.

Machinery and Equipment Used in Contract Packaging

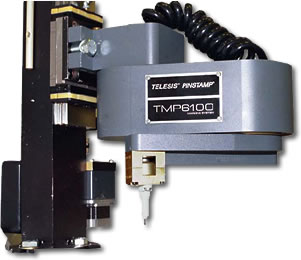

Efficient, high-quality packaging relies on advanced machinery and automation. Contract packaging companies typically utilize:

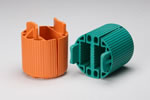

- Plastic Molding Equipment: For producing bottles, blisters, trays, and custom packaging. Includes injection molding, blow molding, and thermoforming machines.

- Heat Sealers: Automated heat sealers are used for clamshell assembly, shrink wrapping, medical device packaging, and food sealing. Adjustable for material compatibility and seal integrity.

- Form-Fill-Seal Machines: Versatile systems that form, fill, and seal pouches, bags, or sachets in a continuous process—ideal for snacks, powders, and liquids. Options include vertical (VFFS) and horizontal (HFFS) configurations.

- Vacuum Packaging Machinery: Removes oxygen from packages for extended shelf life and freshness. Used in food, electronics, and industrial packaging to prevent spoilage or oxidation.

- Label Dispensers and Applicators: Automated systems for applying labels, barcodes, and tamper-evident seals. Essential for regulatory compliance and retail presentation.

- Automated Cartoning and Palletizing: For high-speed secondary and tertiary packaging, optimizing warehouse operations and shipping logistics.

Curious about automation in packaging?

Ask how robotics, vision systems, or digital printing can enhance your packaging line’s speed, accuracy, and flexibility.

Variations: Contract Manufacturing, Filling, Labeling, and Kitting

Contract packaging services often overlap with related outsourcing models, each serving unique needs:

- Contract Manufacturing: Outsourcing both production and packaging to a partner who manages sourcing, manufacturing, and packaging. Ideal for companies without internal infrastructure or seeking rapid market entry.

- Contract Filling: Specialized in precise filling of liquids, powders, gels, or creams into bottles, tubes, pouches, or jars. Essential for pharmaceuticals, cosmetics, food, and chemicals where dosage accuracy is critical.

- Contract Labeling: Application of regulatory, branding, or barcode labels to packaging. Ensures products meet market and compliance requirements (e.g., FDA, EU, GHS labeling).

- Contract Kitting: Assembly of multiple products or components into kits, such as subscription boxes, product bundles, or retail displays—improving logistics and customer experience.

These variations allow businesses to selectively outsource parts of the supply chain or the entire manufacturing and packaging process, gaining flexibility, expertise, and cost advantages.

Fulfillment Services vs. Contract Packaging

While contract packaging focuses on the packaging process itself, fulfillment services cover the entire post-manufacturing supply chain:

- Order Processing: Managing incoming orders from multiple channels (retail, e-commerce, B2B).

- Inventory Management: Storing finished goods in secure warehouses, with real-time inventory tracking.

- Picking and Packing: Selecting products, assembling orders, and packing for shipment.

- Shipping and Logistics: Coordinating courier, freight, or direct-to-consumer delivery, including tracking and customer support.

- Returns Management: Handling product returns, restocking, and customer service.

Many businesses integrate contract packaging with third-party fulfillment services to streamline operations and ensure rapid, reliable delivery to customers worldwide.

Searching for end-to-end supply chain solutions?

Consider providers offering both contract packaging and fulfillment for seamless order-to-delivery management.

What are the Benefits of Using Contract Packaging?

Outsourcing to contract packaging companies offers substantial advantages for brands of all sizes:

- Cost Efficiency

Avoid capital expenditures on specialized equipment, facilities, or labor. Co-packers already have the infrastructure—saving you upfront investments in machinery, warehousing, and staff. According to Packaging World, small businesses can save $50,000–$100,000 or more by using co-packing services.

- Expertise and Quality Assurance

Access to experienced teams with knowledge of industry regulations (FDA, GMP, DOT), advanced machinery, and quality control systems. This reduces risks of recalls, compliance failures, or costly errors. Precision packaging (e.g., ±0.01-inch tolerances) is routine for reputable contract packagers.

- Scalability and Flexibility

Easily ramp up or down production volume in response to seasonal demand, new product launches, or market shifts. Avoid idle lines during slow seasons and scale rapidly during surges—ideal for startups, seasonal brands, or businesses testing new SKUs.

- Faster Time-to-Market

Leverage established supply chains and optimized workflows to bring products to market faster. Co-packers can shorten lead times by weeks or months, enabling competitive advantage in fast-moving sectors.

- Access to Advanced Technology

Benefit from state-of-the-art automation, robotics, and specialty packaging solutions (e.g., tamper-evident seals, ESD protection) without individual investment. This democratizes access to technology for smaller or niche brands.

- Focus on Core Competencies

Free up internal resources to concentrate on product development, marketing, and sales while the co-packer manages the operational complexity of packaging and distribution.

- Risk Mitigation

Transfer operational risks—equipment breakdowns, labor shortages, regulatory changes—to experts. Co-packers are responsible for compliance, adapting quickly to market disruptions (e.g., COVID-19 supply chain pivots).

Real-World Impact:

The $70 billion global co-packing market is driven by the need for speed, compliance, and efficiency. Small and large brands alike report cost reductions (up to 30%), improved regulatory compliance, and smoother scaling by partnering with experienced contract packaging companies.

What to Watch:

Choosing the right provider is critical—vet candidates with site visits, references, and sample runs. Intellectual property concerns and quality control require well-structured contracts and ongoing communication.

How to Find the Right Contract Packaging Service Provider

Selecting a reliable, experienced contract packaging partner is vital for product success and supply chain efficiency. Here’s how to choose the right provider:

- Review provider profiles and capabilities. Look for a proven track record in your industry, with references from similar projects.

- Shortlist 3–4 companies that best match your requirements for volume, speed, compliance, and customization.

- Request quotes and detailed proposals. Ask about turnaround time, quality assurance systems, certifications (ISO, GMP, etc.), and sustainability initiatives.

- Evaluate their flexibility—can they accommodate your growth, changes in demand, or new product introductions?

- Arrange site visits and sample runs to assess facility standards and process transparency.

- Confirm integration with your supply chain—do they offer fulfillment, logistics, or inventory management?

- Ensure clear, transparent contracts outlining quality standards, IP protection, pricing, and performance metrics.

Ready to start?

Explore the list of top contract packaging companies on our site. Contact several to discuss your needs, compare proposals, and choose the partner that aligns best with your goals.

Still have questions?

Ask about specific packaging formats, regulatory requirements, or how contract packaging can support your business growth strategy. Our experts are here to help you navigate the world of co-packing and fulfillment services.

With the right contract packaging partner, your business can unlock new efficiencies, accelerate growth, and deliver high-quality, compliant products to market—faster and more cost-effectively than ever before.

What industries use contract packaging services?

Industries that use contract packaging include food and beverage, pharmaceuticals, consumer goods, personal care, electronics, industrial and chemical products, retail, e-commerce, and seasonal or promotional product sectors. Contract packaging enables businesses in these fields to outsource packaging operations for greater efficiency and compliance.

What are the main benefits of contract packaging for businesses?

The benefits of contract packaging include cost efficiency (by avoiding infrastructure investments), access to expertise and advanced technology, improved quality assurance, scalability and flexibility, faster time-to-market, focus on core business, and risk mitigation through experienced third-party management.

What types of packaging are offered through contract packaging?

Contract packaging services can provide primary packaging (like bottles, blisters, and pouches), secondary packaging (such as cartons, shrink wraps, and multipacks), and tertiary packaging (including pallets and large boxes) to meet product protection, branding, and shipping needs.

What materials are commonly used by contract packaging companies?

Common materials used include plastics (HDPE, LDPE, PET), paper and paperboard, corrugated fiberboard, glass, aluminum, and aluminum foil. Many contract packagers also offer sustainable and recyclable material options for eco-conscious brands.

How do I find and choose the right contract packaging partner?

To find the right partner, review potential providers’ capabilities and experience, request quotes and proposals, arrange facility visits or sample runs, check references, and ensure contracts reflect your requirements for quality, IP protection, pricing, and flexibility. It’s important to align their services with your industry needs, compliance standards, and growth plans.

What is the difference between contract packaging and fulfillment services?

Contract packaging focuses on the packaging process itself, such as filling, labeling, and assembling products. Fulfillment services encompass order processing, inventory management, picking, packing, shipping, and handling returns. Some providers offer both for end-to-end supply chain solutions.

What specialized processes or services can contract packaging companies provide?

Specialized services include contract manufacturing, precise filling of liquids and powders, contract labeling for compliance, custom kitting and assembly, as well as support with regulatory and industry-specific requirements. Advanced automation, robotics, and tailored packaging formats are also available from many providers.

How has the contract packaging industry evolved over time?

Contract packaging has evolved from early food preservation and industrial packaging innovations to encompass modern, technology-driven, and sustainability-focused solutions. Today, the industry supports global brands with high standards for quality, efficiency, and regulatory compliance, and continues to grow alongside e-commerce and changing consumer demands.

Cardboard Tubes

Cardboard Tubes Carrying Cases

Carrying Cases Contract Packaging

Contract Packaging Corrugated Boxes

Corrugated Boxes Dot Peening Machines

Dot Peening Machines Labeling Machinery

Labeling Machinery Marking Machinery

Marking Machinery Packaging Equipment

Packaging Equipment Palletizers

Palletizers Plastic Bags

Plastic Bags Sewing Contractors

Sewing Contractors Tape Suppliers

Tape Suppliers Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services