With our longstanding history of being at the top of the market we are committed to bringing our customers only the best in quality, service and reliability.

Econo-Pak is your contract packaging partner. Experience the assurance of working with a company that understands the intricacies of the packaging industry and is dedicated to elevating your products through exceptional packaging solutions.

Here at XPress 360, we pride ourselves on being a premier provider of contract packaging solutions, offering a diverse range of products, services, and capabilities to meet the varied needs of our esteemed clientele. With our unwavering commitment to excellence and extensive expertise in contract packaging, we stand ready to deliver innovative solutions that excel in quality and reliability...

Here at Vocational Improvement Program, Inc., we take immense pride in our role as a premier provider of contract packaging solutions, offering a diverse range of products, services, and capabilities to meet the varied needs of our esteemed clientele. With our unwavering commitment to excellence and extensive expertise in contract packaging, we stand ready to deliver innovative solutions that...

Here at Sol-Tech Services, we pride ourselves on being a leading provider of contract packaging solutions, offering a comprehensive range of products, services, and capabilities to meet the diverse needs of our esteemed clientele. With our unwavering commitment to excellence and extensive expertise in contract packaging, we stand ready to deliver innovative solutions that excel in quality,...

Contract Packaging Suppliers Comparison Report (Free Download)

Each company’s capabilities, products/services offered, industries served, applications, certifications, quality assurance, and case studies – in one report.

Get The ReportMore Contract Packaging Companies

Contract packaging, or co-packing, has extensive applications across various industries, each with its specific requirements and benefits. In the food and beverage sector, contract packaging services play a critical role in ensuring the efficient and reliable packaging of products.

Applications

Contract packagers have the expertise to handle activities like labeling, sorting, bundling, and assembly, ensuring that products are packaged according to specific requirements and regulatory standards. This is especially important for perishable items and products with short shelf lives, where proper packaging is crucial for maintaining product quality and extending shelf life.

In the pharmaceutical industry, contract packaging is of utmost importance for packaging medications and medical devices. Contract packagers adhere to stringent guidelines and regulations to ensure that products are packaged securely, maintaining their integrity and safeguarding patient safety. They employ advanced quality control measures to prevent contamination and ensure accurate labeling, helping pharmaceutical companies meet regulatory requirements while focusing on their core competencies such as research and development.

Contract packaging is also widely employed in the consumer goods industry, encompassing products such as cosmetics and personal care items. In this sector, packaging serves not only functional purposes but also plays a crucial role in brand identity and consumer appeal. Contract packagers with expertise in specialized packaging materials and techniques help businesses create eye-catching and unique packaging designs that align with their brand image and attract consumers.

Beyond the food, pharmaceutical, and consumer goods industries, contract packaging finds applications in diverse sectors such as electronics, automotive, and industrial goods. In these industries, contract packagers assist in packaging components, parts, and accessories, ensuring that they are protected during transportation and storage. Contract packaging services offer businesses flexibility, scalability, and cost-efficiency, allowing them to outsource their packaging needs to specialized experts while focusing on their core operations.

Overall, contract packaging plays a vital role in multiple industries, providing businesses with the expertise and resources necessary for efficient, compliant, and appealing packaging. By leveraging the services of contract packagers, companies can streamline their operations, maintain product quality, and enhance their brand image, ultimately driving customer satisfaction and business success.

Products Produced

Just a few of the typical packaging products created during contract packaging include: blister packaging, clamshell packaging, pouches, food packaging, shrink wrap, cartons, wrapping and more.

Packaging solutions, including those mentioned above, can be divided into three main categories: primary, secondary, and tertiary. Some companies may need all three forms of packaging for their product, while others may need only one or a combination of two.

Primary Packaging

Primary packaging is the packaging that makes direct or close contact with the product. Sometimes the product has extra packaging around it, or the package itself is the only primary packaging. For instance, if you put a food product in a jar, the jar is the primary packaging because it comes in close contact to the food.

Secondary Packaging

Secondary packaging refers to layers of primary packaging that are used together to provide extra protection to the product inside. Cardboard, foam, and paper are all forms of secondary packaging. Returning to the jar example, if you put several jars of food into one box, the box is the secondary packaging.

Tertiary Packaging

Tertiary packaging is what companies use when they are handling materials in bulk, for shipping and storage in warehouses. Tertiary packaging examples include wooden pallets and shrink wrap. Let’s take a final look at that jar example. Once the jars are in boxes, you may shrink wrap them together. The shrink wrap is the tertiary packaging. In addition, if you store the boxes on a warehouse pallet, you may also consider the pallet tertiary packaging.

History

It’s true that since the advent of bartering and the exchange of goods, packaging has been around in some form or another. However, packaging as we know it today, which is dominated by plastics, did not fully develop until the late 1900s.

Early modern packaging relied on the use of tinplate, a process called tinning. This use of tinplate for packaging began in Bohemia (part of the modern day Czech Republic). English engineer Andrew Yarranton brought it over to England in 1667. By 1725, merchants were selling tinplate boxes from ports in Bristol Channel. By 1805, British manufacturers had made around 80,000 tinplates and exported 50,000.

In the early 1800s, French inventor Nicholas Appert discovered the importance of using airtight containers to preserve food. In response, in 1810, Peter Durand patented the process of canning. Two years later, he sold his patent, and the purchasers opened the world’s first canning factory in London.

The first corrugated box was commercially produced in England in 1817, though corrugated paper did not receive a patent until 1856. Towards the end of the 1800s, paper-based packaging rose in popularity. In 1890, Scottish-American Robert Gair invented pre-cut paperboard.

Some of the greatest motivators of packaging innovation in the 1900s stemmed from the many wars. During World War II, for example, manufacturers had to figure out better ways to get food rations and weapons to the military overseas. Not only that, they had to invent packaging methods that would keep the commodities both safe and secure and easy to access when needed. As a result of packaging difficulties in World War II, the U.S. established packaging-related mil-spec regulations.

There is no inventor of contract manufacturing. Rather, it is a practice that slowly developed over time. For example, in 1952, Michigan State University began offering the first ever Packaging Engineering degree. Just five years later, they opened the MSU School of Packaging.

Since the 1980s, contract packaging companies have focused on creating packaging from post-consumer recycled materials, such as aluminum and paper. They’ve done so in response to government regulations and the influence of the public, which participates through curbside recycling and the like.

In 1992, contract manufacturers in the United States came together to form the Contract Packaging Association (CPA). The formation of this national non-profit trade organization solidified the place of contract packaging in the industrial world. Since 2008, the contract industry has doubled in size, confirming its status.

Materials Process

Before doing anything else, packaging providers must select the right material with which to make the packaging. Some of the most popular packaging materials are plastics, which are generally lightweight and durable. Commonly used plastics include: HDPE, LDPE and PET.

HDPE (High-Density Polyethylene)

HDPE is a sturdy plastic typically used to make primary packaging like bottles and food storage containers. HDPE is corrosion resistant, chemical resistant, strong, resistant to fairly high temperatures and recyclable.

LDPE (Low-Density Polyethylene)

LDPE is a thermoplastic similar to HDPE. Used for primary and secondary product packaging (ex. juice cartons, milk cartons, plastic wrap), LDPE tends to be flexible and corrosion resistant. It is also recyclable, though it is not recycled as often as it should be.

PET (Polyethylene Terephthalate)

Known more commonly as polyester, PET, or PETE, is another sturdy thermoplastic. It is used quite frequently for primary and secondary packaging (ex. bottles, flexible food packaging).

Manufacturers also frequently use paperboard and fiberboard for primary and secondary packaging. Sometimes, they use glass, as well as metals like: aluminum and aluminum foil.

Paperboard

Paperboard, also known as cardboard, is a thick paper-based material. Lightweight, strong and easy to cut, paperboard is often made into cartons and boxes. These paperboard products may serve as either primary or secondary packaging, depending on the application.

Fiberboard

The term “fiberboard” generally refers to a wood product made from wood fibers. Sometimes in packaging, though, it also refers to corrugated fiberboard for boxes. Corrugated fiberboard is a paperboard product. Either way. Fiberboard is strong, rigid and resistant to tears, bending, crushing, impact, etc. In packaging, fiberboard is used for secondary packaging.

Glass

Glass is a non-crystalline amorphous solid. It is transparent and available in a wide range of thicknesses, refraction indexes, impact resistance levels, tensile strengths, etc. Also, it can be modified to be more or less chemical and corrosion resistant. Generally speaking though, it is very inert. In contract packaging, glass is used to create primary packaging products like glass jars and glass bottles.

Aluminum

Aluminum is an element and non-ferrous metal, known to be leak resistant, corrosion resistant and a good retainer of both cold and heat. In packaging, it is mostly used to make aluminum foil, cans and containers.

Aluminum Foil

Aluminum foil, made from aluminum, is a form of primary packaging. It helps keep food and other goods safe by shielding them from outside elements. Such elements include moisture, sunlight, dirt and other contaminants.

Service Details and Design

Contract packaging services begin with package classification. Service providers analyze whether their clients need primary, secondary or tertiary packaging services.

Then, service providers identify and take into account several different application requirements/specifications. These include: marketing, shelf life, quality assurance, packaging regulations, labeling and graphic design, application environment, end-use, child safety regulations, packaging job volume, budget and timelines. Using these considerations, they make decisions on details like: packaging material, packaging design, packaging size, labels, etc. Often, they design the packaging using CAD, document automation and/or rapid prototyping.

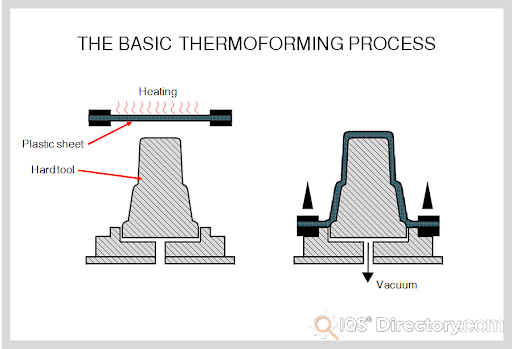

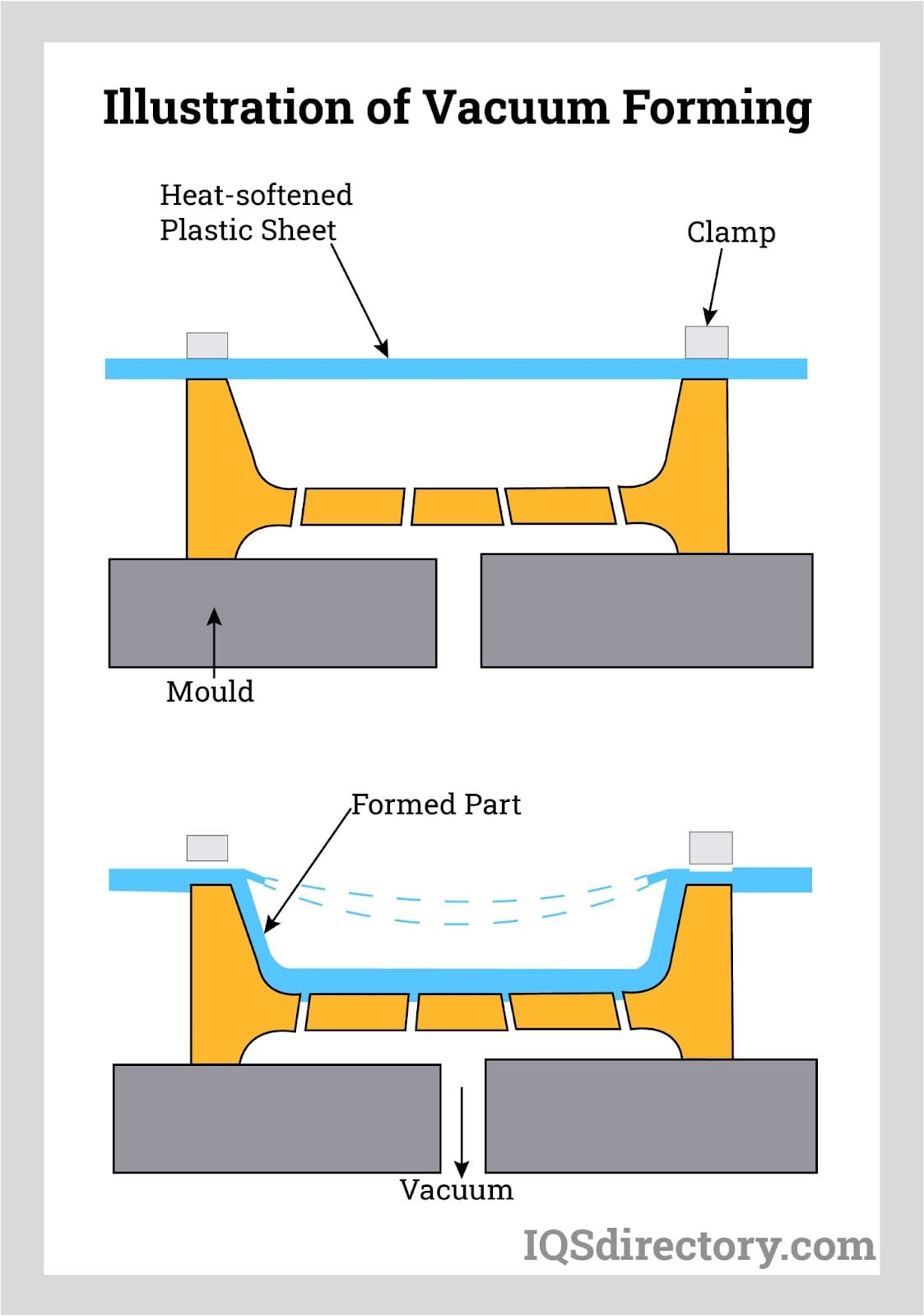

Once they’ve decided on the details, they begin packaging the product. Common packaging processes include: plastic molding, heat sealing and vacuum sealing.

After completing the initial packaging processes, contract packagers go on to customization. Typical customization services include labeling and graphic design. Many contract packagers have in-house graphic design services so that they can design attractive labels for the product to make it more appealing to customers. To create the best designs for you, contract packagers will take into consideration factors such as: cost, usability, material and aesthetics.

One of the most important steps in manufacturing is the packaging of a product. The packaging must be secure, especially during shipping. Specialized products like medical devices or pharmaceuticals must have packaging that meets industry standards and regulations. Most companies request custom packaging design from their contract packager so that their packaging is suited to the needs of their product and customers.

Most contract packaging operations provide their customers with innovative product storage and shipping solutions. They can store the product in bulk, package it, label it with the appropriate information, and ship the packaged product to retail outlets.

Machinery Used

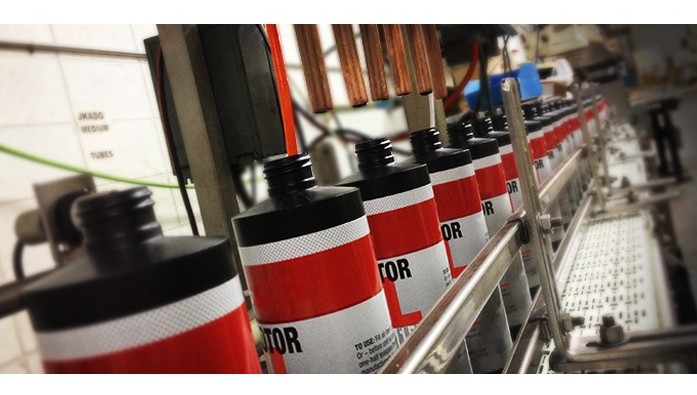

In order to correctly package products and commodities, contract packagers can use a wide variety of different machines and tools. Common ones include: plastic molding equipment, heat seal automated machines form-fill-seal machines, vacuum packaging machinery and label dispensers.

Plastic Molding Equipment

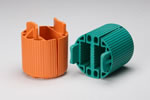

Contract packaging companies use plastic molding equipment to make a variety of primary and secondary packaging (ex. food packaging, blister packaging, pharmaceutical pill packaging, electronic packaging, medical device packaging, etc.) All molding machines, including blow molding machines and plastic injection molding machines, can be adjusted for more size differences, thickness changes, indentations, etc.

Heat Seal Automated Machinery

Heat sealers seal thermoplastics via the direct application of pressure and heat. Heat sealers are used in: clamshell assembly service, shrink wrapping, food packaging and pharmaceutical packaging. They can be modified for different degrees of sealing.

Form-Fill-Seal Machine

Form-fill-seal machines take a flat or v-fold material, form it into a container/bag, then fill and seal it. They usually work on conveyor belts and assembly lines, where they can be adjusted for sterilization purposes, different container types (by adjusting sealing/seaming methods), vertical loading, liquids, solids and more.

Vacuum Packaging Machinery

Vacuum packaging machinery removes atmospheric oxygen from a package, then seals it. The seal is watertight. This packaging machinery is most often used to seal industrial parts, food and electronics like cameras. Like all packaging equipment, vacuum packaging machinery can be customized for your application needs.

Label Dispenser

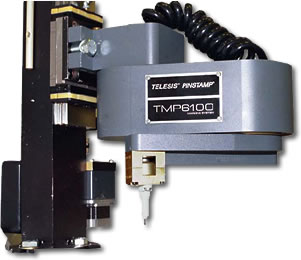

Label dispensers provide information like: pricing, usage guidance, shipping instructions, tampering evidence, product identification and barcoding. Your service providers can adjust it for high industrial loads or small business purposes.

Variations and Similar Processes

Variations of contract packaging exist, catering to specific needs and requirements in different industries. One such variation is contract manufacturing, where a company outsources not only the packaging but also the manufacturing process itself. Contract manufacturers handle the entire production process, from sourcing raw materials to manufacturing and packaging the final product. This approach is particularly beneficial for companies that lack the infrastructure or expertise to manufacture products in-house.

Another related process is contract filling, which focuses specifically on the filling of products into containers or packaging. Contract fillers specialize in filling liquids, powders, gels, or other substances into bottles, jars, pouches, or tubes. This service is commonly utilized in industries such as cosmetics, personal care, pharmaceuticals, and food and beverage, where precise filling techniques and equipment are required to ensure accurate dosage and minimize waste.

In addition to contract manufacturing and contract filling, there are other related processes such as contract labeling and contract kitting. Contract labeling involves the application of labels, barcodes, or other identifying information onto product packaging. This service ensures that products are properly labeled with the required information, such as ingredient lists, product codes, and regulatory markings.

Contract kitting, on the other hand, involves assembling and packaging multiple components or items into kits or sets. This process is commonly used in industries like electronics, where different components need to be grouped together for retail sale or assembly.

These variations and related processes offer businesses a range of options to outsource specific packaging tasks or even entire manufacturing processes. By leveraging the expertise and resources of specialized contract service providers, companies can benefit from cost savings, improved efficiency, and access to advanced packaging technologies and capabilities.

Fulfillment Services

Fulfillment services and contract packaging are related but distinct processes. While contract packaging primarily focuses on the packaging of products, fulfillment services encompass a broader scope that includes activities beyond packaging.

Fulfillment services involve the complete order processing and distribution cycle, from receiving orders to delivering the final packaged products to customers. This process typically includes tasks such as order management, inventory management, picking and packing of products, shipping, and sometimes even customer support.

While contract filling, as discussed earlier, specifically refers to the filling of products into containers or packaging, fulfillment services encompass a wider range of activities. In addition to packaging, fulfillment services may include order processing, product storage, inventory tracking, order fulfillment, and shipping logistics. These services are often outsourced to third-party fulfillment centers or companies specializing in logistics and supply chain management.

Contract packaging can be considered a subset or component of fulfillment services. Once products have been manufactured or sourced, contract packaging services come into play to ensure that they are properly packaged according to specific requirements. This can include tasks such as labeling, bundling, assembling, or kitting. Once the packaging is complete, the fulfillment services take over, managing the rest of the order processing and distribution process until the products reach the end customers.

In summary, while contract filling is a specific aspect of contract packaging that focuses on product filling into containers, fulfillment services encompass a broader set of activities that include packaging as well as order management, inventory management, and shipping logistics. Fulfillment services and contract packaging often work together to provide end-to-end solutions for businesses, ensuring efficient order processing and timely delivery of products to customers.

Benefits

Contract packaging offers many benefits. First, contract packaging service providers have more time to dedicate to shipping, so they can transport goods more efficiently and cost-effectively than others. Likewise, fulfillment services are well equipped to deal with returns that could be complex and time consuming for many companies. Both can also provide you with custom packaging, colorfully designed labels and unique shapes that make your branded product stand out.

Another benefit of contract packaging companies is that they are experts in packaging regulations. They know how to package products in a way that meets FDA or Agriculture standards. From medical items to food products, the lack of appropriate packaging can cause huge delays and financial setbacks. A skilled contract packaging team can avoid these issues and use things like child-safe caps to protect your company from fines or lawsuits.

How to Find the Right Service Provider

For a safely packaged product and/or an expertly branded product, you need to work with an experienced service provider. More than that, you need to work with a contract packaging company that has the vision and drive to provide you with the best work possible. To find a talented and motivated company like this, we recommend you take a look at the list of providers we’ve placed on this page. All of those with whom we partner have proven themselves time and time again in the field.

To discern between them, browse their profiles and websites. Pick out three or four to whom you’d like to speak directly, then reach out individually with your specifications. Make sure they can provide the services you require within your timeframe and budget. Compare and contrast their responses and, when you’re ready, reach out again and get started.

Cardboard Tubes

Cardboard Tubes Carrying Cases

Carrying Cases Contract Packaging

Contract Packaging Corrugated Boxes

Corrugated Boxes Dot Peening Machines

Dot Peening Machines Labeling Machinery

Labeling Machinery Marking Machinery

Marking Machinery Packaging Equipment

Packaging Equipment Palletizers

Palletizers Plastic Bags

Plastic Bags Sewing Contractors

Sewing Contractors Tape Suppliers

Tape Suppliers Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services