With our longstanding history of being at the top of the market we are committed to bringing our customers only the best in quality, service and reliability.

Econo-Pak is your contract packaging partner. Experience the assurance of working with a company that understands the intricacies of the packaging industry and is dedicated to elevating your products through exceptional packaging solutions.

Here at XPress 360, we pride ourselves on being a premier provider of contract packaging solutions, offering a diverse range of products, services, and capabilities to meet the varied needs of our esteemed clientele. With our unwavering commitment to excellence and extensive expertise in contract packaging, we stand ready to deliver innovative solutions that excel in quality and reliability...

Here at Vocational Improvement Program, Inc., we take immense pride in our role as a premier provider of contract packaging solutions, offering a diverse range of products, services, and capabilities to meet the varied needs of our esteemed clientele. With our unwavering commitment to excellence and extensive expertise in contract packaging, we stand ready to deliver innovative solutions that...

Here at Sol-Tech Services, we pride ourselves on being a leading provider of contract packaging solutions, offering a comprehensive range of products, services, and capabilities to meet the diverse needs of our esteemed clientele. With our unwavering commitment to excellence and extensive expertise in contract packaging, we stand ready to deliver innovative solutions that excel in quality,...

More Blister Packaging Companies

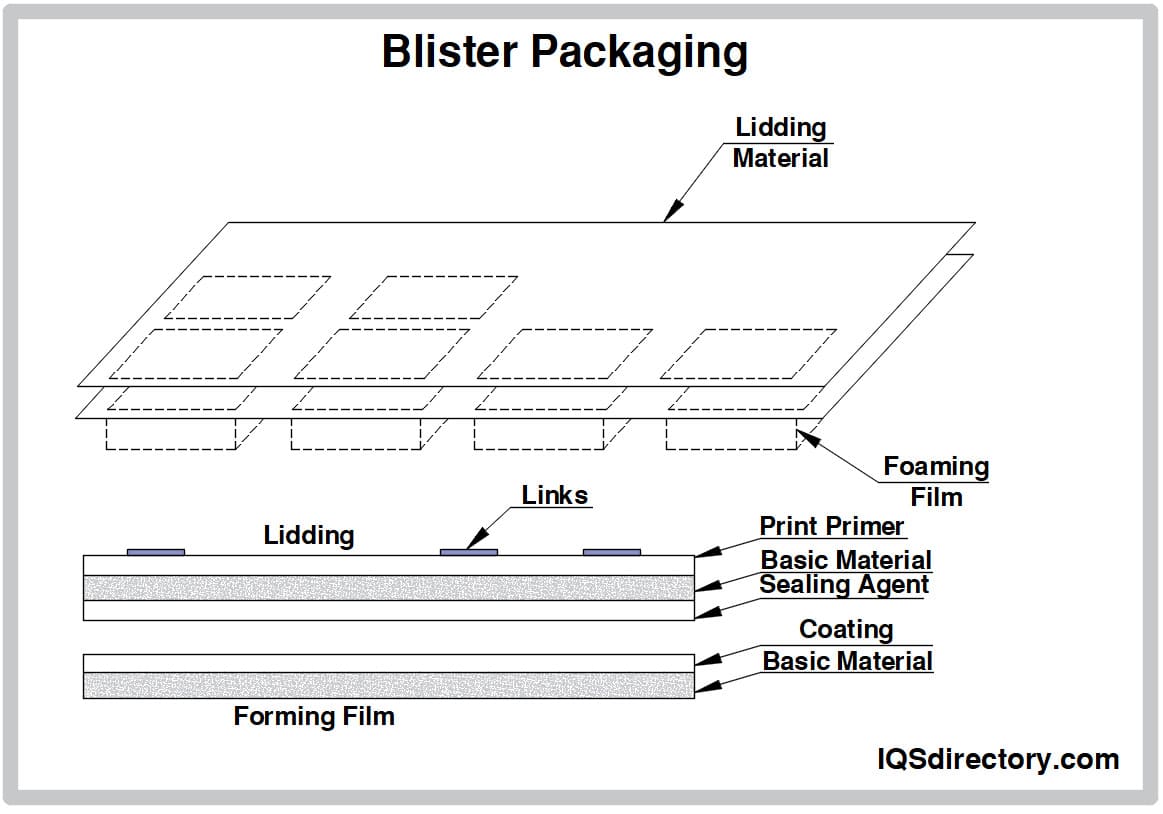

Blister packs are preformed packing materials made up of a malleable lid and a thermoformed plastic cavity. Blister packaging is a form of packaging that is typically used to hold small items, like pills. Blister packs are produced by applying heat on a sheet of plastic and molding it to form a bubble, which is the “blister” that covers the product.

The product is then inserted into the blister in this style of packaging. Various varieties of blister packaging exist, depending on the use. They are used to package consumer goods like groceries, gadgets, toys, and tools due to their inexpensive cost, accessible raw ingredients, and quick processing times. Blister packs are most frequently used by the pharmaceutical industry to package medicinal items such as pills, tablets, capsules, and lozenges.

These packs are constructed as push-through blisters which are a molded plastic containing compartments for individual pills, and a push-through closure made of blister film or lid film and a thin sheet of aluminum foil. The enclosed capsules and tablets are, therefore, hygienically protected and clean from external factors. They are also lightweight, portable, and simple to handle.

How Blister Packaging is Made

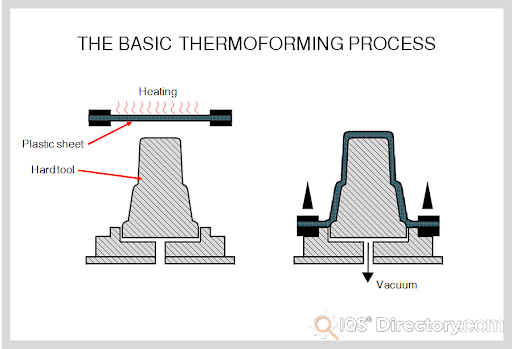

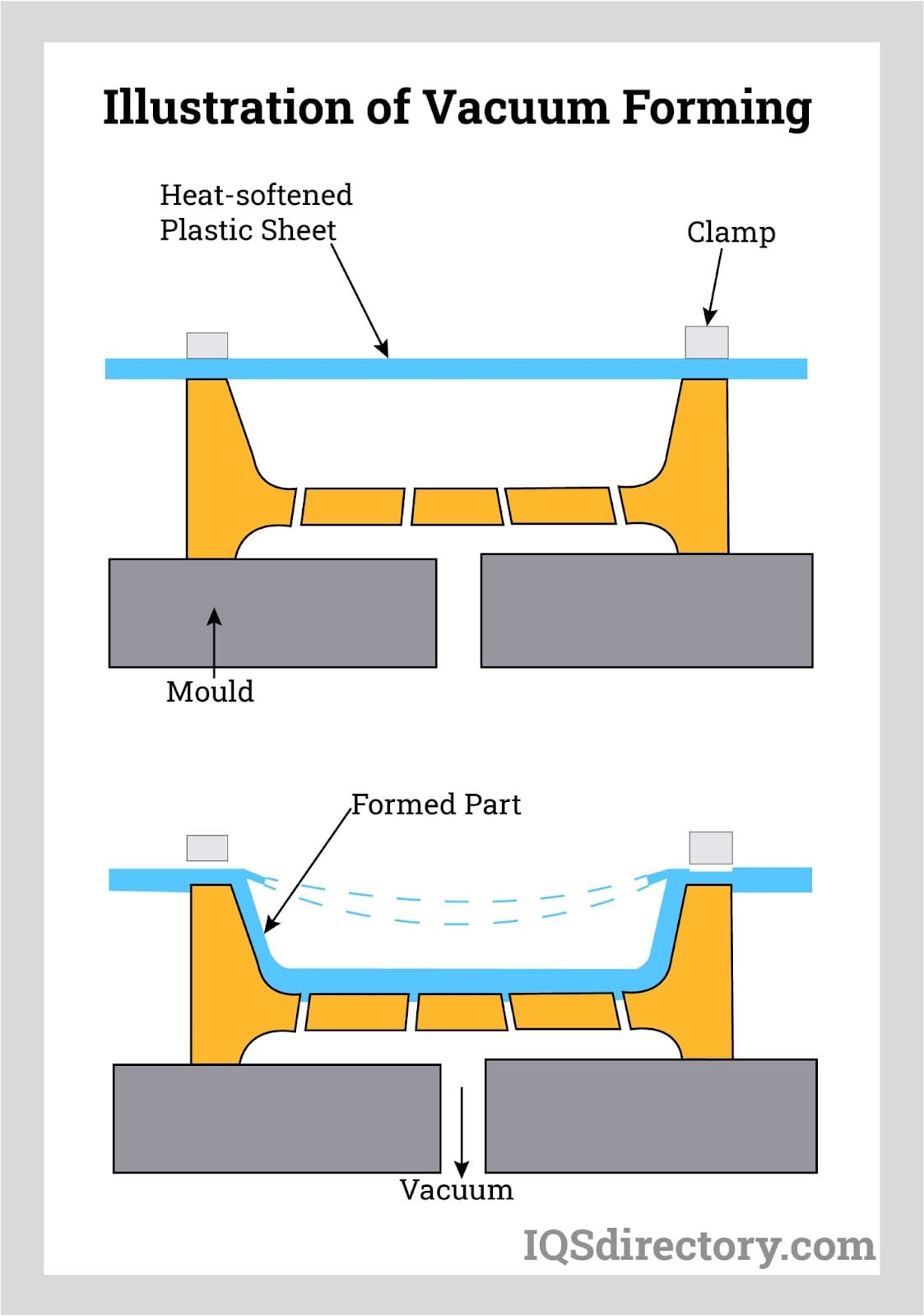

Blister packaging is created through a multistep process. The first step involves the forming of the blisters themselves. There are two methods for creating blisters- cold forming and thermoforming. In cold forming, a (PVC) film laminate is pressed into a mold without the use of heat. PVC (polyvinyl chloride) is commonly used for this process because of its low cost.

With thermoforming, this film is heated across a mold so it can be stretched and better manipulated. The next stage is product loading and this is where the product and blister sizes are checked to see if they are compatible with each other as well as the batch size. Sealing is the third step in the blister packaging process and this occurs after the product is already in the blister; here, the base and the blister are joined together using pressure and extreme heat.

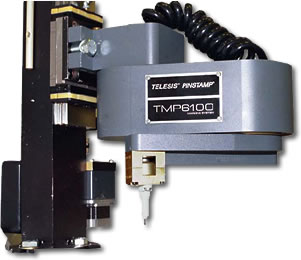

Coding is next. Coding is where important information is embedded on the blister such as the batch size, expiration date and manufacturing date. Perforation and cutting are the last stages of the process as holes are perforated on the product so that opening of the blister becomes easy when one tears it off.

Applications of Blister Packaging

Blister packaging serves many functions. Below is a partial list of potential uses for blister packaging:

- Blister packaging keeps products dry as it provides water resistance. Thermoformed polymer protects the contents in blisters from water, vapor or any liquids. The level of water resistance, however, depends on the material used to create the back cover because, if the blister uses a paper-based rear lid, for example, the water resistance will be very low.

- Blister packaging provides an excellent barrier against, and protection from, oxygen and moisture.

- It protects goods from UV light by using metallized PVC and, as a result, increases the shelf life of perishables.

- Blister packs are tamper evident because they do not close easily once opened. Therefore, these products help ensure the safety of customers.

- Blister packs make items easily visible as they allow clear visibility of the products contained within. Thus, customers are able to have a clear look at the products inside the blisters before they buy.

Advantages of Using Blister Packaging

There are numerous methods for packaging items. Blister packaging provides manufacturing effectiveness, dose precision, and other advantages to consider as mentioned here:

- Portability: Compared to bottled medications, blister packs are more portable. Instead of having to carry an entire container of medication, one can simply take a single dose with them when needed.

- Protection: Blister packaging also has the benefit of maximizing the safety of pharmaceutical packaging because of its completely automated packaging procedure. The consumer is again protected from product tampering since blister packaging provides easy evidence if the package has been previously opened. The blister package's strong sealing ability allows it to be waterproof, moisture-proof, dust-proof, rust-proof, and extends the life of the product held within. As another form of protection, a medicine carried in this type of packaging can lessen the pollution it causes.

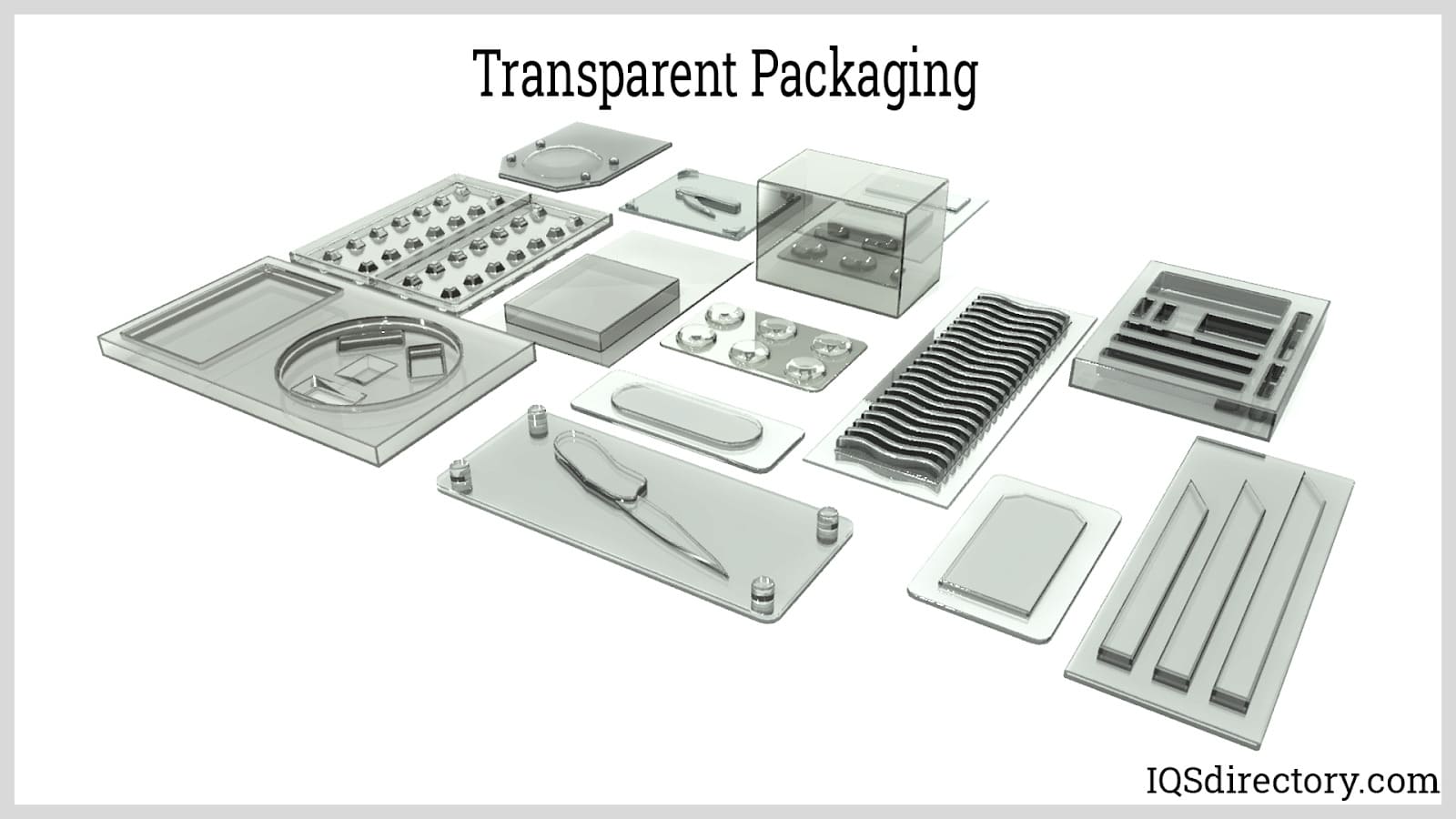

- Variety: Blister clamshell packaging and traditional blister packages are just two of the many assorted varieties of blister packagings that are available. Because of the various options, companies may find this to be the ideal packaging for their goods.

- Marketing: Although typically small in size, a ton of marketing and other information can be provided when packaged as part of a larger unit. The rear card on this kind of packaging can promote the product, give instructions on how to use it, and be eye-catching in the store to attract more customers. This packaging can be both educational and aesthetically pleasing for clients.

- Serving size: Blister packaging is perfect for food and medication storage as it provides the ability to package items based on serving sizes or doses. Each blister packing unit contains a single amount, serving, or dose, making it very simple for individuals to use. To determine whether they have the proper quantity of food or medicine for a dish, they merely open one package and review its contents. Additionally, because it is quicker, there is no need to weigh the components or worry about taking too much medicine.

Limitations of Blister Packaging

There is no one, single packaging method that is perfect for every product or application. Here are the limitations of blister packaging:

- They take a lot of time to produce and they require special processes to manufacture which can be costly.

- It is not always easy to open blister packaging. This fact should be taken into consideration, especially regarding the elderly when attempting to access medications.

Choosing the Proper Blister Packaging Company

To make sure you have the most beneficial outcome when purchasing Blister Packaging from a Blister Packaging Supplier, it is important to compare at least 5 Companies using our list of Blister Packaging suppliers. Each Blister Packaging Supplier has a business profile page that highlights their areas of experience and capabilities and a contact form to directly communicate with the manufacturer for more information or request a quote. Review each Blister Packaging company website using our proprietary website previewer to get an idea of what each company specializes in, and then use our simple RFQ form to contact multiple Blister Packaging businesses with the same message.

Cardboard Tubes

Cardboard Tubes Carrying Cases

Carrying Cases Contract Packaging

Contract Packaging Corrugated Boxes

Corrugated Boxes Dot Peening Machines

Dot Peening Machines Labeling Machinery

Labeling Machinery Marking Machinery

Marking Machinery Packaging Equipment

Packaging Equipment Palletizers

Palletizers Plastic Bags

Plastic Bags Sewing Contractors

Sewing Contractors Tape Suppliers

Tape Suppliers Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services